Act-in MES I for smart manufacturing

Solution Description

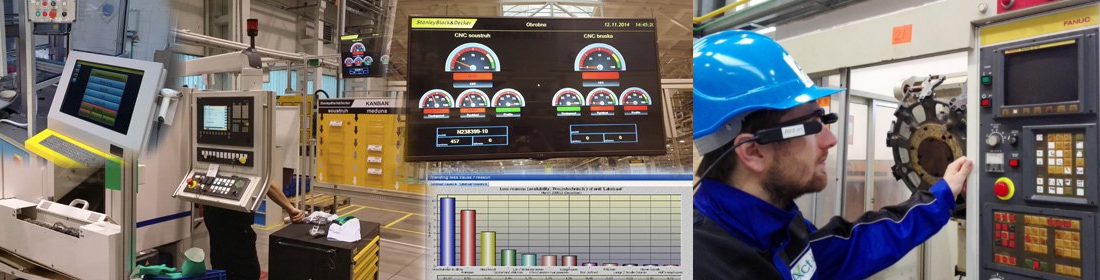

Act-in MES is a modern shopfloor management system based on more than 30 years of experience of the international Act-in Group with technical and process support of industrial production companies in many European countries and many production sectors.

The main modules focused on online data collection, monitoring, production planning and control, production documentation management, maintenance management, quality management and SPC, process control and traceability are successfully used by leading manufacturers in the automotive and aerospace industries, mechanical engineering, electrical engineering, plastics industry, furniture and wood processing industry, paper industry, textile industry and food industry in the Czech Republic, Germany, Great Britain, Holland, Belgium, Slovakia, France, Austria, Switzerland, Poland, Serbia, Hungary, Portugal, United States and Mexico.

The system comes to the Czech market from the Czech development and implementation center, which is a guarantee of fast and efficient implementation, including subsequent service support. Act-in experts guide customers from the initial analysis, solution design to the implementation and delivery of the system with maximum knowledge of the environment of manufacturing companies and their needs to increase productivity and efficiency of their production.

Act-in MES has a modular structure and customers can choose individual modules and submodules according to their current needs and financial capabilities. The main division of modules is according to their primary focus on online data collection from machines and workplaces, production monitoring, production planning and control, maintenance management, quality and traceability management, production visualization and performance analysis.

The modularity of the system leads to its successful deployment in both large and small and medium-sized enterprises in record time and with a fast return on investment.

In addition to high modularity, the key features of the system and the capabilities of the implementation team include easy integration with third-party systems such as ERP systems SAP, Axapta, Navision, Oracle, JD Edwards, MfG Pro, Helios, Karat, Dimenze, QI, Infor, etc., as well as easy connection and online reading of data from all types of machines, lines, stations and production, control and handling equipment with various control systems and communication protocols.

Supported Production Types

| system support for individual types of production: 0 - least support; 10 - highest support |

| Discrete: 9 | Batch: 5 | Continuous : 3 |

Supported Manufacturing Areas

| the system supports a given production areas by significant number of functionalities and has several active projects implemented in each given area |

Production monitoring and control, Production scheduling, Maintenance management, Quality, Production logistic

Supported Manufacturing Classification

| the system is successfully implemented in given industries and has active references |

Aerospace & Defense, Automotive, Consumer Goods, Electronics & Mechatronics, Food & Beverage, Furniture & Wood Processing, Heavy Metal Industry, Machinery & Tools, Pharmacy, Painting, Paper & Pulp, Metal Fabrication, Plastic & Rubber, Press & Printing, Textile & Leather Industry, Cables and Wires Production

Essential Functionalities

| the system supports these essential functionalities already in standard solution and they are used in already implemented active projects |

Control & Monitoring of Production, Scheduling, Production Logistics, Paperless Production, Production Traceability, Nonconforming Production Management, Production Quality Control, Process Data, Maintenance, Machine Data Collection, Performance Analysis, Production Visualization

Extended Functionalities

| the system supports these extended functionalities already in standard solution and they are used in already implemented active projects |

SPC (Statistical Process Control), Machine Configuration (DNC, ...), Escalation and Alarm System, Personnel Qualification, Energy Management, Augmented Reality, Dynamic Manufacturing Control, Packaging Unit Management, Change Management, Tool Management, Material Flow Control, Production of Unique Pieces

Machine Data Collection

| the system has implemented support for individual areas of machine data collection and they are used in implemented active projects |

Machine performance (cycles, lengths, ...), Tool performance (cycles, lengths, ...), Nonconforming production, Machine states, Process parameters, Control stations, Machine configuration (NC programs, ...), Data historization

User System Customization

| the system allows to trained end users to create following customization systems without the need of system integrator involment |

Editing and creating reports, Integration of reports into the application, Creating and editing custom screens, User editor of visualization screens, User localization, Plugin architecture, User configuration of system behavior

Active Implementation in Countries

| the system has an active implementations in the following countries |

Austria, Belgium, Czechia, Denmark, France, Germany, Hungary, Mexico, Poland, Portugal, Serbia, Slovakia, Switzerland, United Kingdom

Contact Information

| System Producer |

|

| System Integrator |

Act-in CZ, s.r.o. | Digitization of manufacturing industry |

| Product Web Site |

Act-in |

English (UK)

English (UK)  Česky (CS)

Česky (CS)