Overall Equipment Effectiveness (OEE) is a quantitative indicator of the efficiency of production equipment. It provides a measurable comparison of the efficiency of individual production facilities and entire manufacturing companies. It includes multiple components affecting overall efficiency, which can be independently evaluated and used to eliminate found losses (organization, performance and quality).

Efficiency or effectiveness?

Let's first look at words “efficiency” and “effectiveness”. These terms are often used interchangeably, and even within a single text, the authors often use them as synonyms. However, their meaning is not the same. Efficiency (generally the ratio between the benefit of an activity and the cost of an activity), while effectiveness is meaningfulness (the relationship between a goal and its effect).

The traditional TPM concept defines OEE as Overall Equipment Efficiency. However, the newer concept sees OEE as Overall Equipment Effectiveness. Hereinafter, OEE stands for

Overall Equipment Effectiveness.

Overall Equipment Effectiveness

The Overall Equipment Effectiveness (OEE) indicator was created in the 1960s by Seiichi Nakajima of Nippon Denso. In the late 1980s, this methodology became known through the expansion of TPM. In the mid-1990s, it was applied in the field of semiconductor components to increase the productivity of production equipment. Gradually, the methodology also adopted other industrial production sectors.

The core concept of this methodology lies in the following formula:

OEE = Useful time of equipment / Disponible time of equipment,

where:

- Useful time of equipment – the time, when the equipment produces OKs

- Disponible time of equipment – the time, when the machine should produce

The difference between useful time and disposable time is given by usage, performance and quality. The most common expression of the relationship for the calculation of OEE uses the following three indicators:

OEE = Availability x Performance x Quality,

Where:

- Availability (usage) – production time / disponible time

- Performance – operating time / production time

- Quality – useful time of equipment / production time

Following definitions and formulas are used for calculation of given indicators:

Availability

The ratio between operating time and disponible time. Operating time is the time when the machine is really on and running. Disponible time is the time when the machine is expected to run. The calculation is done through this formula:

Availability = Operating Time / Loading Time,

Where:

- Operating Time – real time when the machine is running

- Loading Time – time when the machine is expected to run

Performance

The ratio between the real output and the planned output. The following formula is used for the calculation:

Performance = Total Output / Potential Output,

Performance = (Total Output * Ideal Cycle Time) / Operating Time,

Where:

- Total Output – total number of produced products

- Potential Output – planned amount of products

- Ideal Cycle Time – planned cycle time (for one product)

- Operating Time – real time when the machine is running

Quality

The ratio between the number of OK products and the number of all products. The following formula is used for the calculation:

Quality = Good Output / Total Output,

Where:

- Good Output – number of OKs produced

- Total Output – number of all products produced

Example of OEE calculation

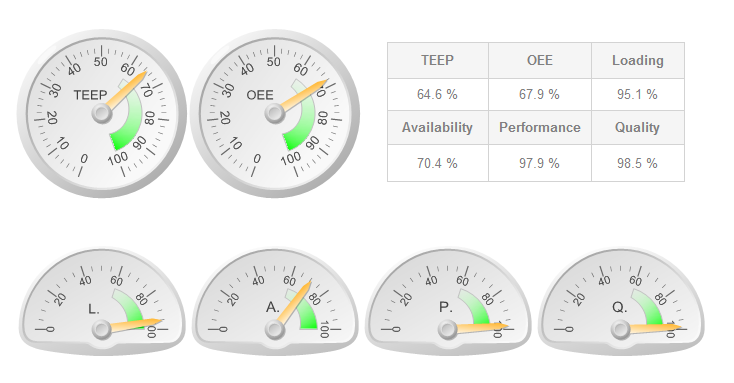

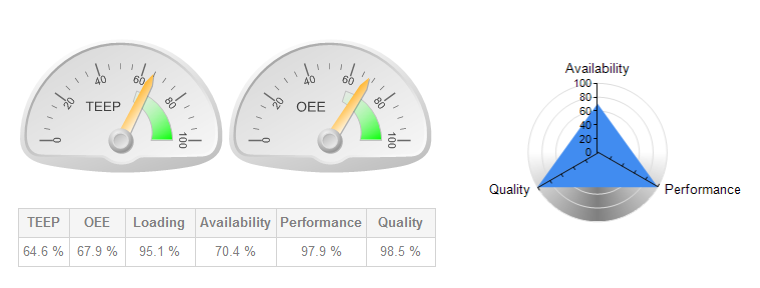

Let’s have a look at one example calculation of OEE:

The disponible time for an equipment is 22 hours, 50 minutes. The machine runs on 3 shifts.

- The machine was running for: 16 hrs, 4 min, 29 sec

- The machine produced: 2000 pcs

- From which was OK: 1970 pcs

- Planned cycle time is: 28,3 s

Availability = Operating Time / Loading Time

Availability = 16,075 hod / 22,83 hod = 0,704 = 70,4 %

Performance = (Total Output * Ideal Cycle Time) / Operating Time

Performance = (2000 * 28,3 s) / 16,075 hod = 0,979 = 97,9 %

Quality = Good Output / Total Output

Quality = 1970 ks / 2000 ks = 0,985 = 98,5 %

OEE = Availability x Performance x Quality

OEE = 0,704 * 0,979 * 0,985 = 0,679 = 67,9 %

Top companies are reported to have achieved OEE of 85% after successful TPM implementation. However, most manufacturing companies achieve OEE at around 60%. However, it is necessary to take into account how and on what basis this number was calculated. The quality and method of data collection play an important role. See the OEE Tools chapter for more details.

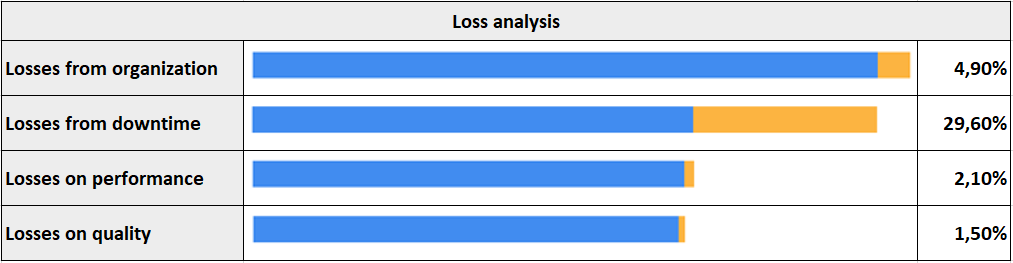

OEE losses

OEE is a key Total Productive Maintenance (TPM) tool to reduce and eliminate The Six Big Losses that reduce production.

Six big losses are divided into three basic areas:

Losses from downtime

- Defects on equipment

- Setting and adjusting

Losses on performance

- Inactivity and short breaks

- Reduction of speed

Losses on quality

- Nonconformity and repairs

- Losses during starting of machine

If we include a derived TEEP in the loss analysis, then we get the losses given by the production organization. These losses are caused by outages for which production is not planned (one-shift or two-shift production, holidays, holidays ...).

By analyzing loss areas, we should be able to identify the causes and sources of losses. This will allow us to find ways to increase the efficiency of the use of machines and equipment.

OEE Tools

An important aspect for the calculation of OEE indicators is the collection of input data. The data collection strategy can range from primitive manual records to sophisticated automated solutions.

Manual data collection is based on paper forms in which production operators record events affecting production efficiency. These are production feedbacks (produced pieces, non-conforming pieces, ...), causes and duration of downtime, reasons for power loss, etc. Sophisticated solutions are then based on automatic collection of these data from machines, continuous registration of operators for performed activities, continuous reporting of nonconforming production and deviation production.

The difference between manual and automated data collection is mainly in the following areas:

- Data quality - data acquired manually contains both intentional and unintentional errors and inaccuracies (given by the initial registration by the production operator or by a copy into the superior system), they do not take into account short-term downtime and making them bothers the operators and administration.

- Availability of data – manually acquired data is not available in real time. They are acquired predominantly at the end of the shift and, due to manual entry, they get into the higher systems with a further delay.

Automatic data collection (from machines or electronic operator registration) eliminates errors and inaccuracies and provides real-time data. Thus, OEE evaluation can be made for both discontinued and ongoing production.

OEE automation systems usually include tools for visualization, analysis and reporting of OEE results. Such tools should include custom reporting capabilities, aggregation functions, loss analysis tools, summary and detailed reports across machines to entire manufacturing businesses.

Derived OAE, OPE and OFE indicators are used to relate OEE indicators to enterprise-wide levels, which we will look at in the next chapter.

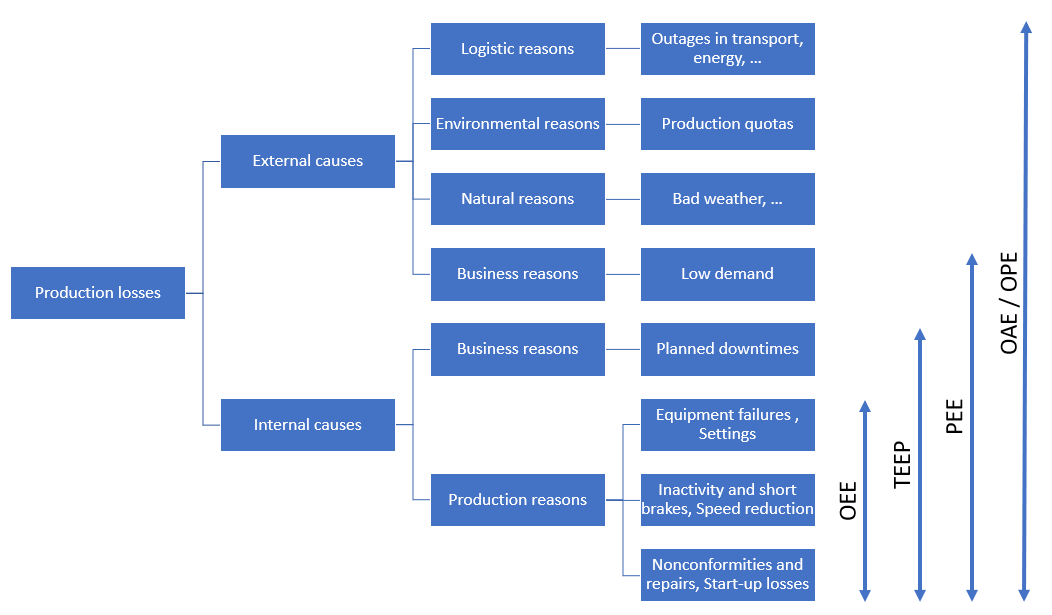

Derived indicators TEEP, PEE, OAE, OPE, OFE, OTE, CTE

In addition to OEE, other derived indicators have emerged in response to the new efficiency assessment requirements. Some of them (TEEP, PEE, ...) move at the device level, while others (OAE, OPE, OFE, ...) extend OEE to the enterprise level. Let's review their basic characteristics:

TEEP - Total Equipment Effectiveness Performance

The best known of the derived Total Equipment Effectiveness Performance (TEEP) indicators takes into account planned downtime. While OEE quantifies how efficiently the equipment is used within the planned time (shifts), TEEP assesses the equipment's efficiency relative to calendar time (ie 24 hours a day, 7 days a week and 365 days a year). If the plant is scheduled to run 24 hours a day, 7 days a week and 365 days a year, then TEEP corresponds to OEE. TEEP can be expressed as:

TEEP = Useful time of equipment / calendar time,

or:

TEEP = Loading x Availability x Performance x Quality = Loading x OEE,

where

- Loading – disponible time / calendar time

- Availability –production time / disponible time

- Performance –pure production time / gross production time

- Quality –useful production time / pure production time

In case we look at the previous example of OEE calculation and we add TEEP indicators, we get following results:

Loading = 22 hours 50 min / 24 hours = 0,951 = 95,1 %

TEEP = 0,951 * 0,704 * 0,979 * 0,985 = 0,679 = 0,646 = 64,6 %

PEE - Production Equipment Efficiency

Another derived indicator is PEE (Production Equipment Efficiency). The main difference of this indicator lies in the weights of the sub-indicators (Availability, Performance and Quality). While for OEE all sub-indicators have the same importance, for PEE the importance of the sub-indicator is given by the set weight.

PEE calculation formulas vary based on the type of production for which it is used:

Discrete production

For discrete production, the sub-indicators remain the same as in the case of OEE, only the weights of the individual indicators are added:

PEE = (Availability)k1 x (Performance)k2 x (Quality)k3,

where

- ki – weight of the indicator “i”, 0 < ki ≤ 1, ∑ki = 1

Continuous production

The PEE formula in continuous production is defined as:

PEE = (Availability)k1 x (Attainment)k2 x (Performance)k3 x (Quality)k4 x (PSE)k5 x (OU)k6,

where:

- ki – weight of the indicator “i”, 0 < ki ≤ 1, ∑ki = 1

- Availability – reflects the planned downtimes and corresponds to “Loading” indicator from the TEEP methodology

- Attainment – reflects unplanned downtimes and corresponds to “Availability” indicator from the TEEP methodology

- Performance – corresponds to “Performance” indicator from the TEEP methodology

- Quality – corresponds to “Quality” indicator from the TEEP methodology

- PSE – Product Support Efficiency takes into account the transaction losses

- OU – Operating Utility takes into account the losses from demand

In the case of continuous production, it is assumed that there are no adjustment losses and are therefore not taken into account in the PEE calculation.

OAE/OPE – Overall Asset/Production Effectiveness

Overall Asset Effectiveness (OAE) and Overall Production Effectiveness (OPE) indicators are based on OEE methodology. They have been designed to meet the specific requirements of different sectors and therefore appear in practice under different definitions. Of all the above indicators, they include the largest spectrum of calculated losses - used to identify and measure all losses associated with the entire production process.

Both have the same meaning as regards the application of indicators in industry, but differ in the concept of production losses. OAE quantifies production losses by output, while OPE by time.

OFE – Overall Factory Effectiveness

The OFE (Overall Factory Effectiveness) methodology is used to express the efficiency of the entire manufacturing plant. If there are multiple production steps on multiple devices in a production, classic OEE cannot be used at the enterprise level. While OEE focuses on the efficiency of individual devices, OFE evaluates all devices together. It includes relationships and interactions between different devices and processes in the calculation.

The production environment consists of subsystems that can be divided into 4 basic groups:

- Series (serial, linear)

- Parallel (parallel, concurrent)

- Assembly (joining, montage)

- Expansion (disassembly, expansion)

Using these 4 groups of subsystems, the entire production plant can be modeled. Methodologies such as Overall Throughput Effectiveness (OTE) or Cycle Time Effectiveness (CTE) examine the subsystem efficiency.

OTE expresses the ratio between actual output and theoretically possible output. The methodology is closely linked to simulation techniques for increasing production productivity. CTE is then the ratio between the theoretical cycle length and the actual cycle length.

Miroslav Patočka

MES PHARIS Analyst

UNIS, a.s. | Control & Information Systems

Note: The graphics used in the article were taken from the system MES PHARIS.

English (UK)

English (UK)  Česky (CS)

Česky (CS)